I was really expecting to have some more pictures by now – things in clamps, oozing with glue, etc., but I just hit the first of what will probably be several snags along the way. As of today, no additional wood has been cut for the guitar. Ron and the rest of the Alembic electronics team have been sitting around trying to figure out how to get the custom electronics compliment to fit in to the body! Apparently, nobody has asked for my exact combination of electronics to fit in this body shape.

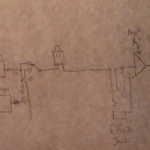

They think they’ll have some answers for me by the end of the week, but some options to get everything to work right include:

- Make the body shape slightly bigger – Even though they say I would never notice the increased size unless they told me, I’m not sure I want to do that just yet.

- Have Alembic hardwire some of the electrical connections, instead of using modular connectors – Alembic usually uses modular connectors in their wiring schemes, to make servicing easy. These connectors take up space, though, and space is at a premium in the body cavity. Since I’m handy with a soldering iron, I’m pretty confident that this option could work… but will it yield enough space.

- Simplify the electronics compliment – surprisingly, I’m open to this option. The Alembic electronics afford a lot of pickup combinations (typically 27!), and I’m not so sure I need to tweak at that level. It’s more important to me to quickly dial in the sound I want. I’m going to talk with Alembic today, and give them my thoughts on this.

In order to test out the placement of electronics, Alembic is using a dummy body, the same size and shape I originally called for. Smartly, they don’t want to cut the wood I selected until they are absolutely sure everything is going to fit!